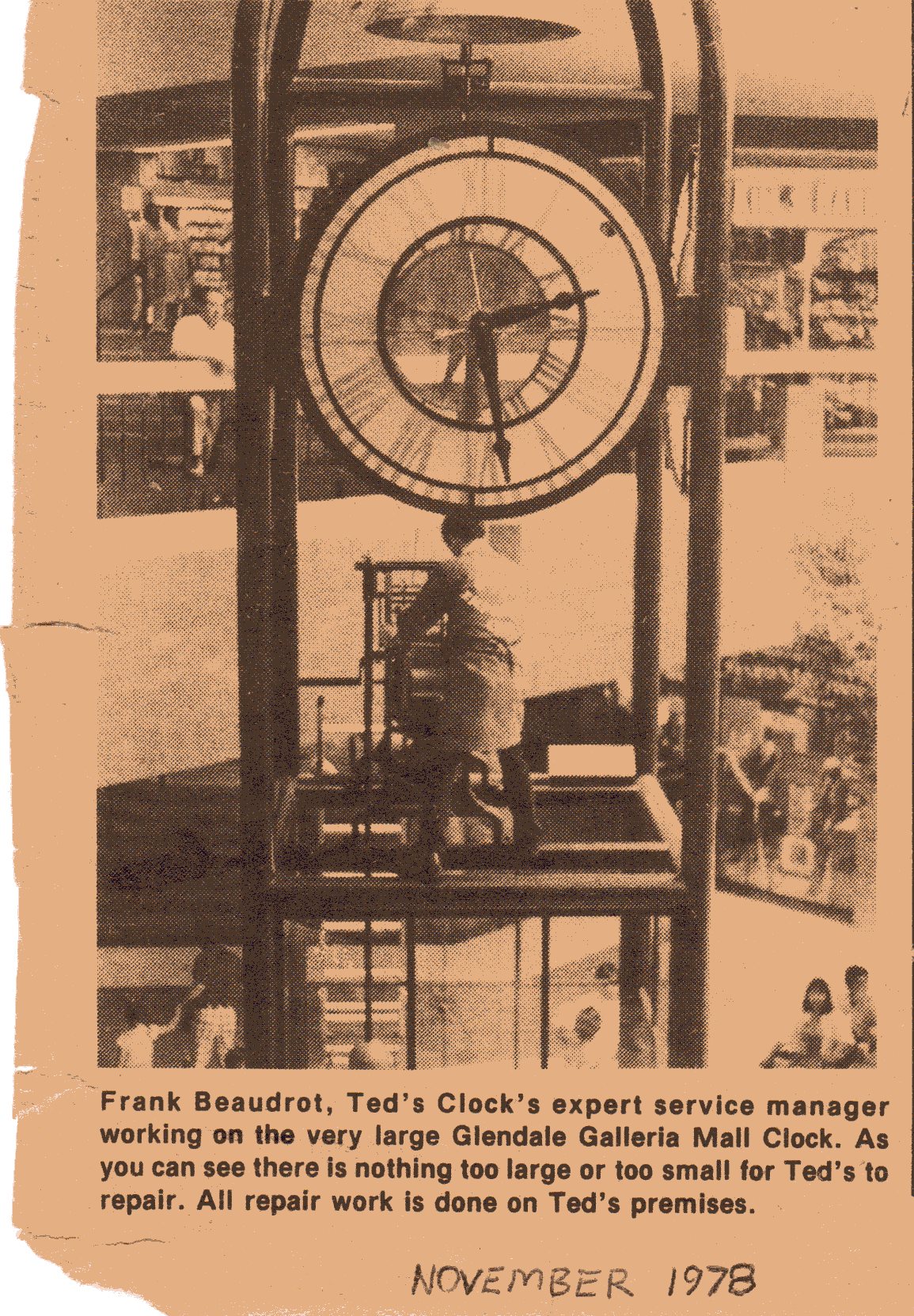

My Very First Tower Clock. Here’s a photo I dug up that was taken back in 1978. At the time, I was the service manager for Ted’s Clock Emporium in Glendale, California. (you can read more about that on my “About” page on my website). The local newspaper must have been having slow news day so they came and did a human interest piece on Ted’s. Yes, that’s me standing precariously on the rails. You can’t see it in the picture, but under my smock is a safety harness.

The story behind this clock is that the movement was originally from a bank building that was destroyed in the 1906 San Francisco earthquake. The Mall developer had a new “tower” built for it near the food court. It had been motorized for automatic winding and not long afterwards, it started giving them trouble. Ted’s had a store located in the mall so we were the ones management called to repair it. This was truly “learning on the job” for me.

I chuckle every time I read the caption under the picture, “All repair work is done on Ted’s premises”. Clearly this one wouldn’t have fit on my bench!!